NT Series

General

In order to meet demands of customers in South East Asian countries (ASEAN) such as wide range of applications, high durability, high working efficiency, long continuous working hours, and operation comfort, ISEKI spent years to do market surveys and field tests to develop a strategic NT tractor model for main rice-growing areas of ASEAN.

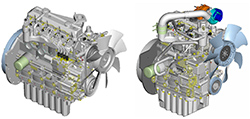

1. Powerful Engine

Direct injection powerful engine of NT tractor has large displacement and their stable torque at all engine speeds ensures power in reserve whatever the high or continuous load. Field work with tractor at lower engine rpm decreases fuel costs and increases engine life as well as improving the operating environment through reduced level of noise and vibration. In addition, larger fuel tank enables longer continuous operation time of tractor.

2. High durability

The full synchronized Main Shift for NT554/548 models provides the operators with smooth gear changes between speeds of 1⇔2, 2⇔3, 3⇔4 without having to completely stop the tractor. This enables easy and comfortable operation, which saves time and efforts, and improves working efficiency. Moreover, steering column-mounted synchronized shuttle shift allows the operator to easily shift between forward and reverse direction with full depression of clutch and brake pedal.

Additionally, NT series are equipped these features to achieve heavy duty work in long working hours. “High durability clutch” enables to work easily in case of using Front-Dozer. “Big size front axle housing” is equipped for heavy duty. “Water sealed Front Axle” by high quality oil seal is standard feature for working in the paddy field. “Breezier pipe” helps to circulate the air to keep the oil temp in the Front Axle.

NT series have great hydraulic lift capacity with iron casted chassis, it enable to be equipped with various implement. It also offers comfortable operation and is not troublesome for operator to work with any implements and conditions.

3. Comfortability

The full-open hood provides easy access to the different systems of engine that required a periodic inspections such as air intake system, fuel system, electrical system, lubrication system, and cooling system. The one-piece hood also saves time an effort of operators when doing engine maintenance.

Ergonomic designed operator space provides effective and comfortable work. Control levers are located nearer to the operator side to contribute efficient work and to reduce operator’s fatigue even for long operation. Our wide and flat floor provides enough space for operator.

NT tractors are equipped with a deluxe instrument panel with tachometer, fuel gauge and water temperature gauge, allowing operators to monitor the tractor’s operation and performance and make suitable operating decisions based on the information provided by the gauges of the panel.